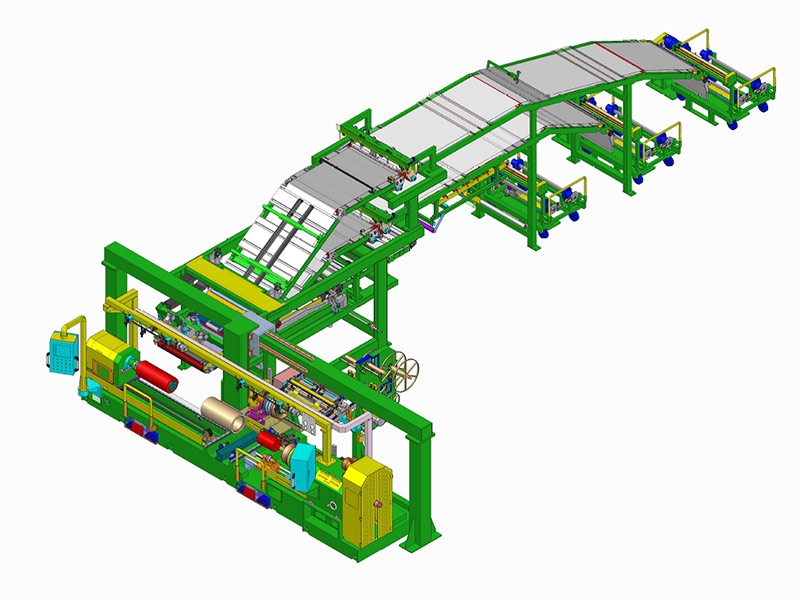

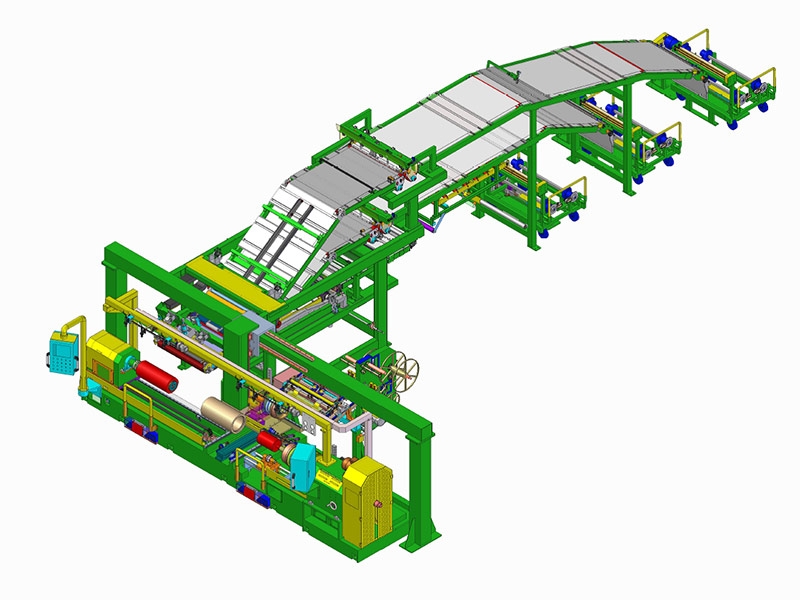

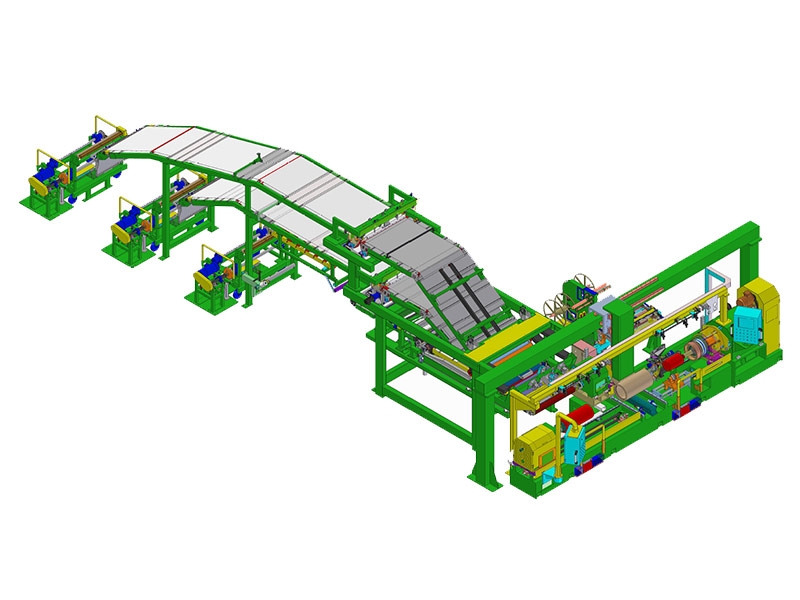

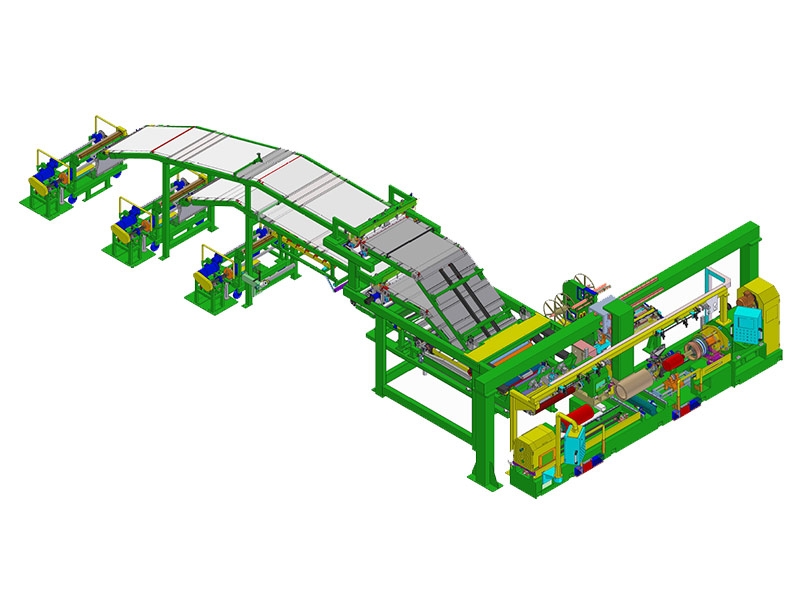

SMI-SL

Product Introduction

| Model | SMI-SL |

| Size Range:□ 1215 / □1316 / □1518 / □1720 / □2024 / □2226 | |

| Applicable Tire | PCR, HP |

| Bead Diameter | 12”~26” |

| Machine Design | Dual Drum Design (Tire Building Drum + Band Building Drum) |

| Drum Type | 10 Slices sliding type Drum |

| Band Building Drum | Max. W= 850mm |

| Band Transfer Ring | To Transfer the band from band building drum to tire building drum |

| Building Width | □MIN240 ~ MAX560mm □ MIN280 ~ MAX600mm |

| Bead Setting | Servo cylinder |

| Apex Turn up Mill Method (Option) |

□ With Apex high turn up mill assembly (patent) □ Without Apex high turn up mill assembly (Bladder turn up) |

| Building Width Change | Auto |

| Laser Light Positioning | Servo control |

| I/L, S/W Let-off | Cart or Reel |

| PLY Let-off | Cart or Reel |

| I/L Cutting | Auto measuring & cutting on the servicer |

| PLY Cutting | Auto measuring & cutting on the servicer |

| S/W Cutting | Both sides auto cut after drum one turn |

| Component Centering | Each component auto centered by Web Guide system and then forward to union applicator |

| Component Application | Union Applicator auto Applying |